Glass Strengthening Process

Frankenstein™ Copied Link

Using DC electricity, potassium ions are forced to exchange with sodium ions within the surface of the glass. By alternating the current flow and finishing off with a molten salt immersion, all faces of the sample are strengthened in a greatly reduced timeframe.

Details

In this technique, an advantage is taken of electric field assistance. [1]

Electrodes laden with KNO3 salt are deposited on the opposite faces of a thin glass sheet.

The assembly is heated to an appropriate temperature.

A DC field is applied to the opposite faces which drives potassium ions from the anode plate to the cathode plate.

After a predetermined time, the field is reversed; potassium ions enter from the opposite face.

Using a careful choice of time and current density, the specimen is treated through multicycles of switching the polarity.

The multi-cycling yields a flatter and balanced stress profile at the two surfaces.

Again, by suitable choice of cycling, specimen warp which is commonly obtained in thin float glasses can be greatly controlled.

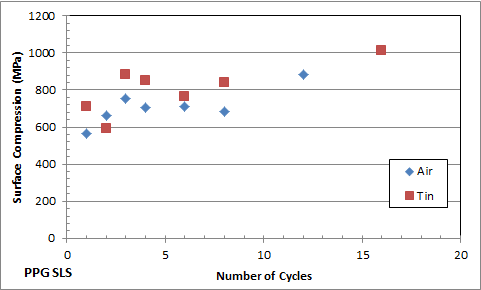

Because the total time for the field-assisted ion exchange can be as little as a few minutes (generally ~1/2 hour), the CS values obtained in a typical soda lime silicate glass composition can be as high as 800-900 MPa (versus the traditional 500 MPa).

Further, the incorporation of a short (~ ½ hour) molten bath immersion-based ion traditional exchange can strengthen the specimen edges to protect against edge originated failures in a dropped device.

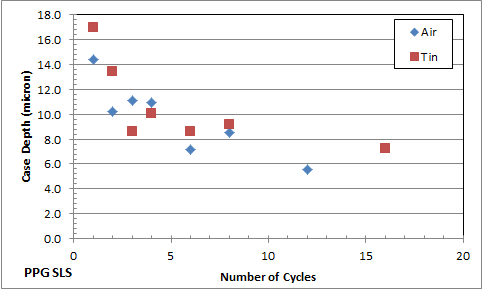

The evolution of CS and DOL with cycling is shown in the figure below for a soda lime silicate float glass.

Frankenstein™ technology may be particularly useful for strengthened cover glasses for personal mobile electronic devices.

Surface Compression

Case Depth