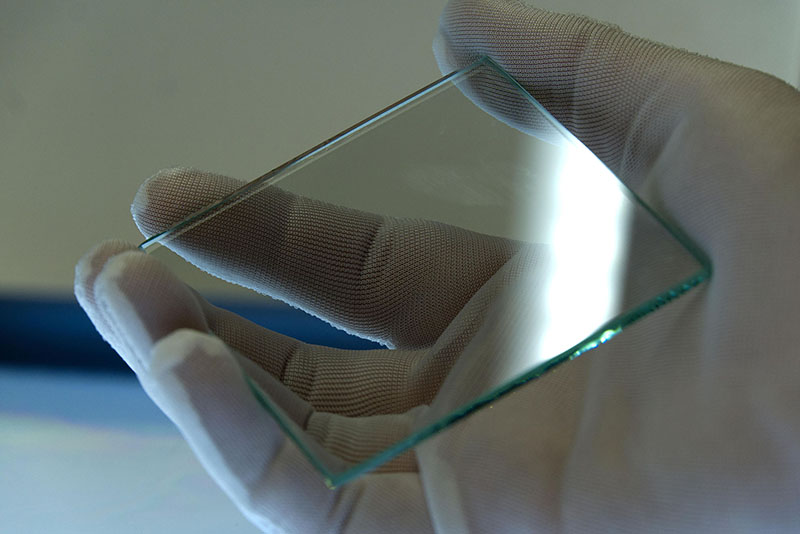

Chemically Strengthened Borosilicate Glass for COVID-19 Vaccine

Read More About Sumo™Glass Chemical Strengthening Experts

Science • Technology • Experience

Our strengthening processes using an alkali ion exchange mechanism dramatically increase fracture strength, fatigue resistance, thermal shock resistance, and abrasion resistance. We specialize in borosilicate, aluminosilicate, and soda-lime silicate glass strengthening and offer strengthening processes for various other compositions, such as optical glasses. The glass experts at Saxon may be able to provide 50 to 800% increases in design strength using your current glass compositions.

Fracture Strength

Glass breaks when tensile stress acting on surface flaws exceeds theoretical strength of the glass at the tip of a flaw. The ion exchange process generates a high magnitude of surface compression which must be overcome by the applied tension to create a fracture.

Fatigue Resistance

The compressive forces reduce the velocity of existing subcritical flaws from propagating under the action of a given applied load even in a corrosive environment. Even with cycling load on and off, the flaw dimensions remain relatively constant, thus the fatigue resistance of glass increases.

Thermal Shock Resistance

A larger magnitude of temperature difference across the wall of a glass product needs to be given to overcome the added compression, thus improving the material's resistance to thermal shock.

Abrasion Resistance

When an indenter is withdrawn after indenting, the surface compression acts to expand the surface; the permanent plastic impression is hence smaller in size. Glass surface becomes harder. Surface damage, such as scratches, scuffs, and other abrasions from handling and use, is consequently reduced.

Process Overview

What occurs during chemical strengthening?

Smaller host sodium ions on the glass surface are replaced by larger potassium ions, therefore forcing it into compression.

This creates closure stress on cracks, thereby reducing the chance of crack propagation.

Furthermore, the surface compression all but eliminates problems of "delayed failure"; i.e. time-dependent weakening under load and increases abrasion resistance.

The ion exchange process is carried out at temperatures below the glass transition temperature while the glass is still nearly solid.

Our Products & Services

Our strengthening techniques have provided consistent and timely results to the pharmaceutical industry for over 25 years.

Contact Us

Let's discuss strengthening your product, get in touch with us!